Kawasaki Thermal Engineering Co., Ltd

-

High efficiencyYou can reduce fuel cost by around 10% and achieve better environmental performance such as reducing CO2 emissions.

High efficiencyYou can reduce fuel cost by around 10% and achieve better environmental performance such as reducing CO2 emissions. -

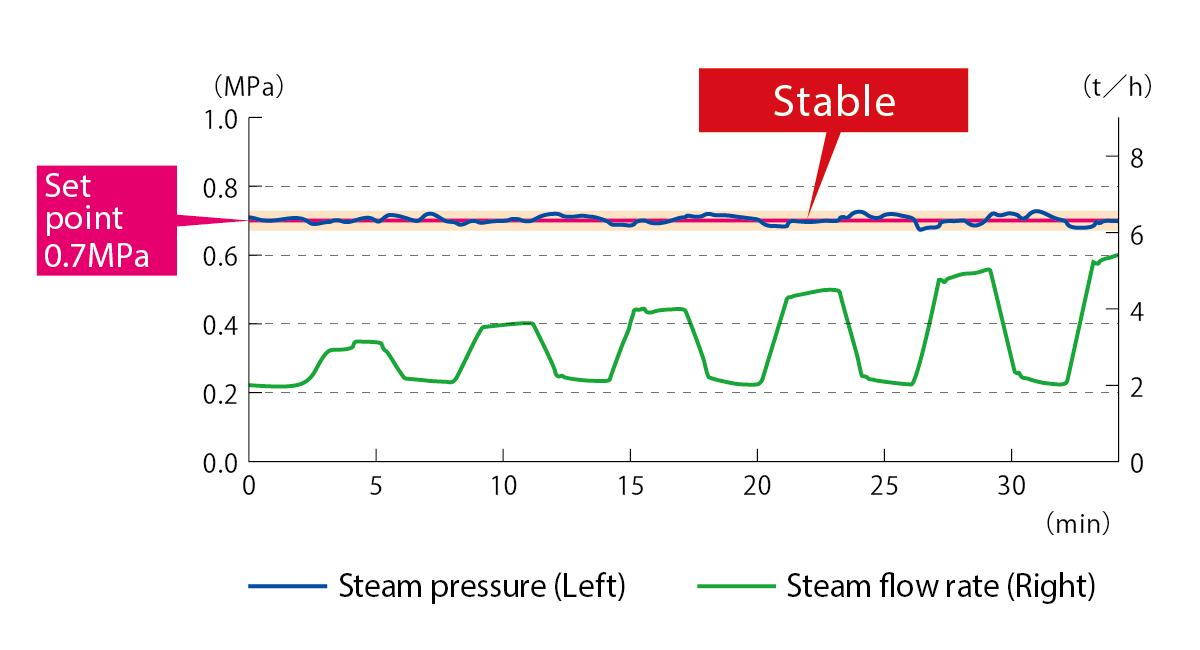

High quality steamKawasaki boiler can supply stable steam pressure and steam dryness 99.5% or more by PID control for combustion and water feeding.

High quality steamKawasaki boiler can supply stable steam pressure and steam dryness 99.5% or more by PID control for combustion and water feeding.

Once Through Boiler - IF Series

Once-through boiler is one of Water tube boiler composed of water tubes and there are single-tube types and multi-tube types.

We manufacture multi-tube type Once-Through boiler, with high efficiency and compact size.

Offering all-round excellence in the field of package boilers

-

Energy saving and lower environmental impact

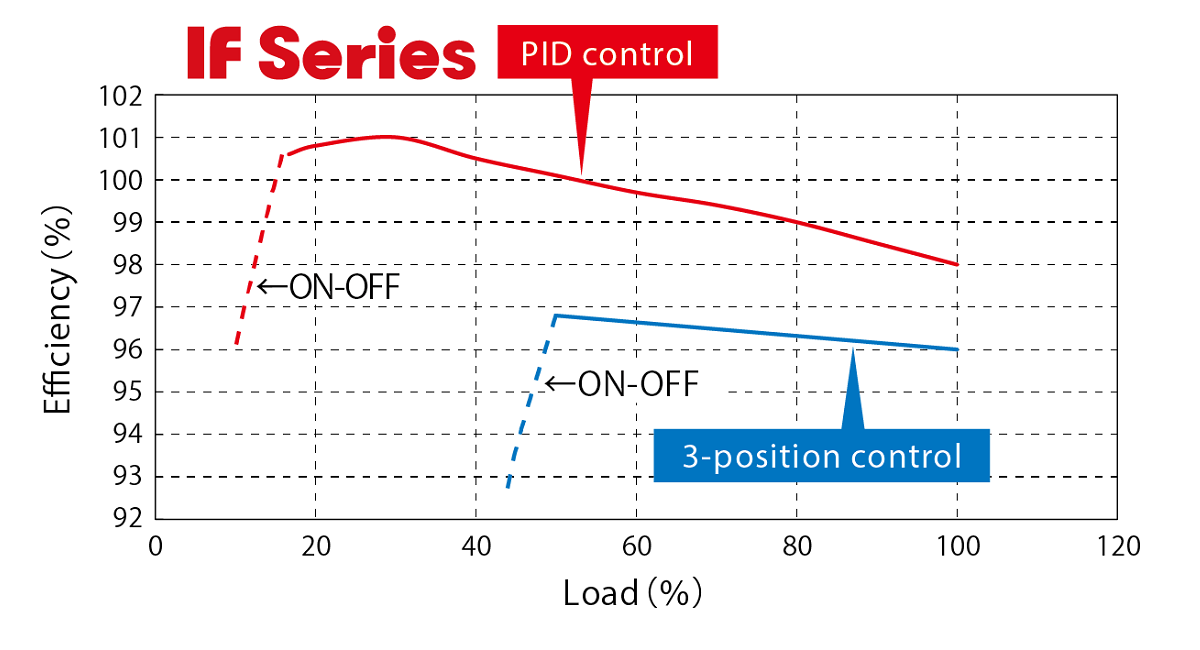

IF series is equipped with “PID combustion control” and "Inverter control of draft fan and feed water pump” as standard, which contributes reducing fuel, electricity cost and CO2.

-

Fast steam up

It depends on capacity, but in general, it takes about 40 minutes for Water tube boiler, about 1 hour for Fire (smoke) tube boiler, IF boiler can supply steam in 5 - 10 minutes from cold start.

-

High efficiency by multi-unit boiler operation

PID multi unit control system automatically selects number of unit and combustion ratio depending on the steam load. By such efficiently optimized operation, fuel consumption, power consumption and heat loss can be substantially reduced.

-

High-quality steam

The following are the reasons for high-quality steam.

(1) PID combustion control

(2) Continuous feed water control

(3) High-performance centrifugal steam water separator

(4) Water feeding to steam water separator. These functions prevent fluctuation of water level amount and temperature of feed water. It enables to supply stable and high-quality steam. -

High durability of Once-through boilers

With KTE’s unique technologies and professional manufacturing methods we developed throughout our history of over 120 years, we realized long-life time which significantly exceeds conventional Once-through boilers. Durability of IF series helps to reduce investment cost in long-term.

High durability of Once-through boilers

Round design for pressurized part

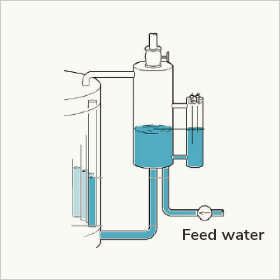

Steam water separator with built-in deaerator

Water feeding to steam water separator

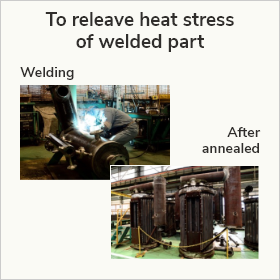

Annealing of pressurized part

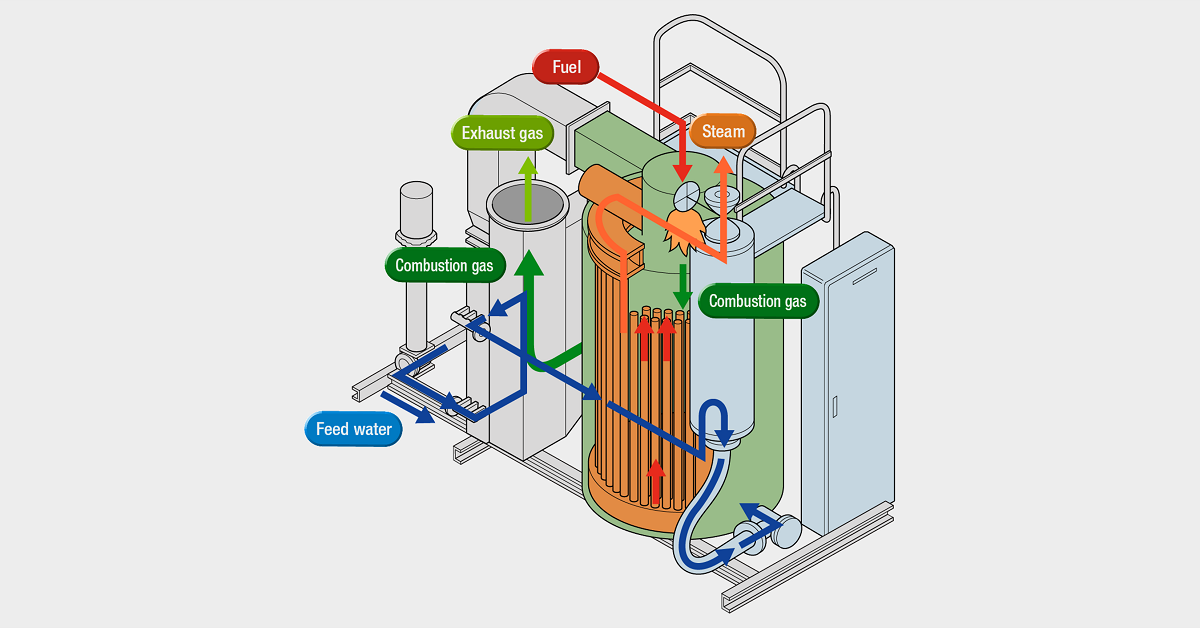

Principle of Boiler

Multi tube once-through boiler is composed of water tubes where water is supplied from one end of tube and steam is extracted from the other side. Small amount of boiler water can generate steam quickly. Installation space can be saved due to compact size.

Our system & Service

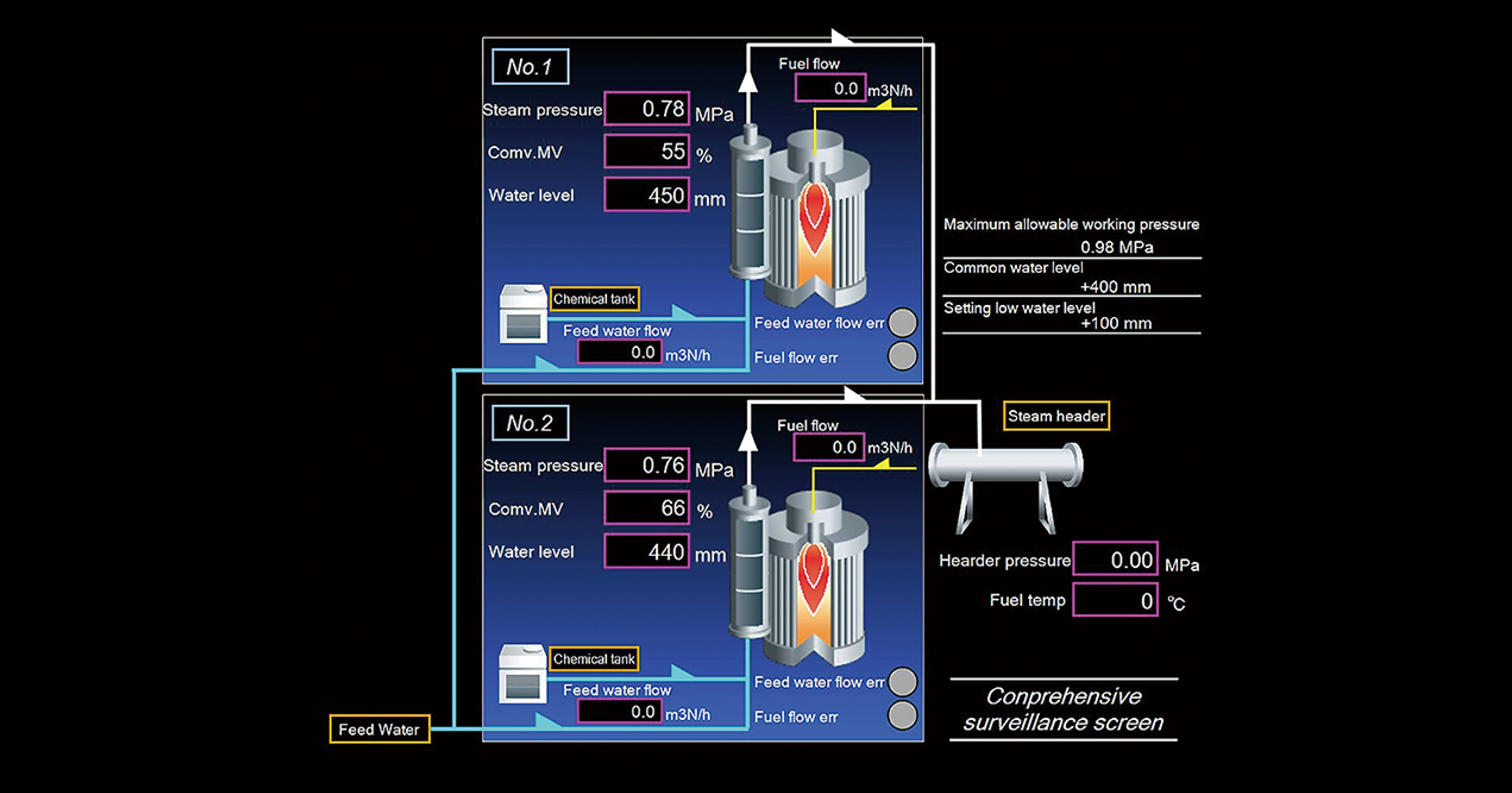

'EveryFIT' is data logging system. Your daily management becomes easier.

- This system monitorizes every facility.

- Monitoring screen and daily/monthly report can be customized freely according to the customer’s application.

- Not only boiler data signal but also auxiliary facilities signals can be input to ‘Every FIT’

Monitor operating condition via wireless communication or internet communication.

- When abnormal error occurs, operation data will be sent to the remote monitoring system.

- Our service engineer and distributor check the error before site visit. It contributes to shortening the time for trouble shooting.

At our showroom, we display Once-through boiler WILLHEAT (WF-3000 x 2 units, WF-2000 x 4 units) and IF series (IF-6000 x 1 unit). We can demonstrate the actual operation in accordance with your own condition. Please see how much energy can be saved with our boilers.

Catalogue Download

Contact

Kawasaki Gas Turbine Asia Sdn Bhd (702680-X)

No. 12A, Jalan Tiang U8/92,Seksyen U8, Bukit Jelutong Industrial Park,

40150 Shah Alam, Selangor Malaysia.

- Established date : 2005/07/12

- 603-5870-0300

- https://kga.com.my/